25

يوليو

الفرق بين أكياس البولي إيثيلين عالي الكثافة ومنخفض الكثافة

أكياس البلاستيك من أفضل أنواع الأكياس التي بإمكانك الاعتماد عليها للتعزيز من علامتك التجارية والتحسين من تجربة الشراء في محلك التجاري. ودائمًا لديك خياران رئيسيان وهما أكياس البولي إيثيلين عالي الكثافة ومنخفض الكثافة وفي هذا المقال سنتعرف عليهما وعلى الفروقات الجوهرية.

ما هي أكياس البولي إيثيلين عالي الكثافة؟

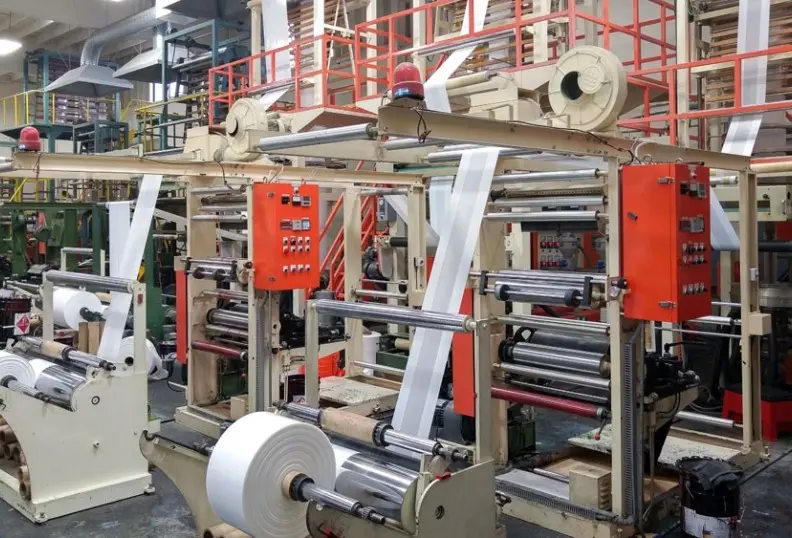

أكياس البولي إيثيلين عالي الكثافة (HDPE) هي الأكياس المصنوعة من مادة البولي ايثيلين عالية الكثافة مقارنة مع المنخفض الكثافة ليوفر قوة وصلابة أكبر وكثافة تتراوح بين 0.93 و0.97 جرام/سم³. في البداية كان يُستخدم في تصنيع المنتجات البلاستيكية مثل الخراطيم البلاستيكية ومن ثم طوّر ليُستخدم اليوم في تصنيع الأكياس البلاستيكية عالية الكثافة وبفضل خاصية بولي إيثيلين المقاومة للتآكل، فإنها ستحصل على أكياس بلاستيك مقاومة لمختلف الظروف الطبيعية.

قد يهمك: أنواع خامات أكياس البلاستيك واستخداماتها

ما هي أكياس البولي إيثيلين منخفضة الكثافة؟

الأكياس المصنوعة من البولي إيثيلين منخفضة الكثافة (LDPE) تتميز بكثافة منخفضة تتراوح بين 0.91 و0.93 جرام/سم³ ومرونة عالية للتشكيل على حسب ما تريده وفي نفس الوقت شفافة لتستخدم في حمل المنتجات الغذائية والفواكه والخضروات.

الفرق بين أكياس البولي إيثيلين عالي الكثافة ومنخفض الكثافة

في هذه الجزئية من المقال سنتناول الفروقات بين أكياس البولي إيثيلين عالي الكثافة ومنخفض الكثافة، والمتمثلة في الآتي:

|

وجه الاختلاف |

أكياس البولي إيثيلين عالي الكثافة |

أكياس البولي إيثيلين منخفض الكثافة |

|

المرونة |

أقل مرونة |

شديد المرون |

|

القوة |

أقوى |

أقل |

|

الشفافية |

أقل |

أعلى |

|

الكثافة |

أعلى |

منخفضة |

هل أكياس البولي إيثيلين صحية؟

مختلف الأكياس المصنوعة من أكياس البولي إيثيلين عالي الكثافة أو المنخفض صحية وغير مضرة بالبيئة، ففي البداية إنها مقاومة للتقادم وقد تم حساب عمرها بخمسين (50) سنة على الأقل وتحافظ على مقاومتها وأدائها في جميع الظروف البيئية ولا تتلوث بسهولة، ولا تحتوي على مواد سامة وهي قابلة للتنظيف بسهولة للغاية.

ختامًا، الفرق بين أكياس البولي إيثيلين عالي الكثافة ومنخفض الكثافة يكمن في المرونة والقوة التي يمنحها لك كل نوع من أنواع الأكياس لتستخدم ما يناسبك وما يعزز من علامتك التجارية.