19

أغسطس

ما هي استخدامات البولي ايثيلين في مجال صناعة الأكياس؟

البولي ايثيلين من المواد الرئيسية المستخدمة في صناعة أكياس البلاستيك موفر لمزايا قوية وسهولة تشكيل وتعديل، من خلال هذا المقال سنقف على استخدامات البولي ايثيلين في مجال صناعة الأكياس البلاستيكية.

ما هو البولي ايثيلين؟

البولي ايثيلين polyethylene هو مادة بلاستيكية تستخدم في مختلف الصناعات التي يدخل فيها البلاستيك ومن أشهرها الأكياس. تتكون من مجموعة من العناصر التي تُسمى بوليمرات الاصطناعية المستخدمة في مختلف جوانب التعبئة والتغليف من صناعة الأكياس البلاستيكية والزجاجات والحاويات والمفارش الأرضية. وتجدر الإشارة إلى أنه يتم إنتاج أكثر من 100 مليون طن من البولي إيثيلين سنويًا للأغراض التجارية والصناعية.

استخدامات البولي ايثيلين في مجال صناعة الأكياس

يوجد العديد من استخدامات البولي ايثيلين في مجال صناعة الأكياس وهي:

1- استخدام البولي ايثيلين في صناعة أكياس التسوق

اكياس التسوق المصنوعة من البولي ايثيلين من أشهر الأكياس المستخدمة في المحلات التجارية من المولات والصيدليات والمحلات التجارية التي تتيح للمستخدمين شراء منتجات بعينها. أكياس التسوق متاحة بخامات أكياس وسمك مختلف على حسب ما يريده العميل.

2- استخدام البولي ايثيلين في صناعة أكياس الهدايا

إذا ما كان لديك محل لبيع الهدايا أو ترغب في بيع أكياس الهدايا مباشرة للعملاء المهتمين بها، ففي هذه الحالة يجب أن تكون أكياس الهدايا المصنوعة البولي ايثيلين ضرورية ضمن سلة الشراء الخاصة بك. متوفرة بمقاسات وأحجام مختلفة لتناسب مختلف الحاجات والرغبات.

3- استخدام البولي ايثيلين في صناعة أكياس المخبوزات

أكياس المخبوزات عنصر أساسي في كافة المخابز لضمان التحسين من تجربة المستخدم، يتم صناعة أكياس المخبوزات من حبيبات ( CPP السلفان الأوروبي ) أو البولي ايثيلين بمقاسات حرة دون الحاجة للالتزام بقياسات.

4- استخدام البولي ايثيلين في صناعة أكياس الشيال

أكياس الشيال المصنوعة من البولي ايثيلين تتميز بجودتها العالية ومرونتها المميزة لاستخدامها في مختلف المحلات التجارية. بالتالي تُعد من الأكياس المطلوبة بشكل كبير من مختلف المحلات والعلامات التجارية لتضمن لك أفضل خدمة عملاء ممكنة.

5- استخدام البولي ايثيلين في صناعة أكياس تغليف المنتجات

أكياس تغليف المنتجات من أنواع الأكياس المهمة والضرورية لكل العلامات التجارية والشركات العاملة في مجال التجارة الإلكترونية. من خلالها يتم تغليف الطلبات عبر أكياس الفلاير ذات الجودة العالية وضمان توصيلها للمشتري بأفضل جودة ممكنة دون التأثر بالظروف الطبيعية أو عمليات الشحن.

أنواع البولي ايثيلين

يوجد نوعين رئيسين من البولي ايثيلين وهما:

1- أكياس البولي إيثيلين عالي الكثافة (HDPE): هي الأكياس المصنوعة من مادة البولي ايثيلين عالية الكثافة مقارنة مع المنخفض الكثافة ليوفر قوة وصلابة أكبر وكثافة تتراوح بين 0.93 و0.97 جرام/سم³. تُستخدم في تصنيع المنتجات البلاستيكية مثل الخراطيم البلاستيكية ومن ثم طوّر ليُستخدم اليوم في تصنيع الأكياس البلاستيكية عالية الكثافة.

2- البولي إيثيلين منخفضة الكثافة (LDPE): تتميز بكثافة منخفضة تتراوح بين 0.91 و0.93 جرام/سم³ ومرونة عالية للتشكيل على حسب ما تريده وفي نفس الوقت شفافة لتستخدم في حمل المنتجات الغذائية والفواكه والخضروات.

الفرق بين البولي ايثيلين عالي الكثافة والبولي ايثيلين منخفض الكثافة

يوجد مجموعة من الفروقات بين البولي ايثيلين عالي الكثافة ومنخفض الكثافة وهي:

|

وجه الاختلاف |

أكياس البولي إيثيلين عالي الكثافة |

أكياس البولي إيثيلين منخفض الكثافة |

|

المرونة |

أقل مرونة |

شديد المرون |

|

القوة |

أقوى |

أقل |

|

الشفافية |

أقل |

أعلى |

|

الكثافة |

أعلى |

منخفضة |

لتتعرف على كامل الفروقات بين البولي ايثيلين عالي الكثافة والبولي ايثيلين منخفض الكثافة

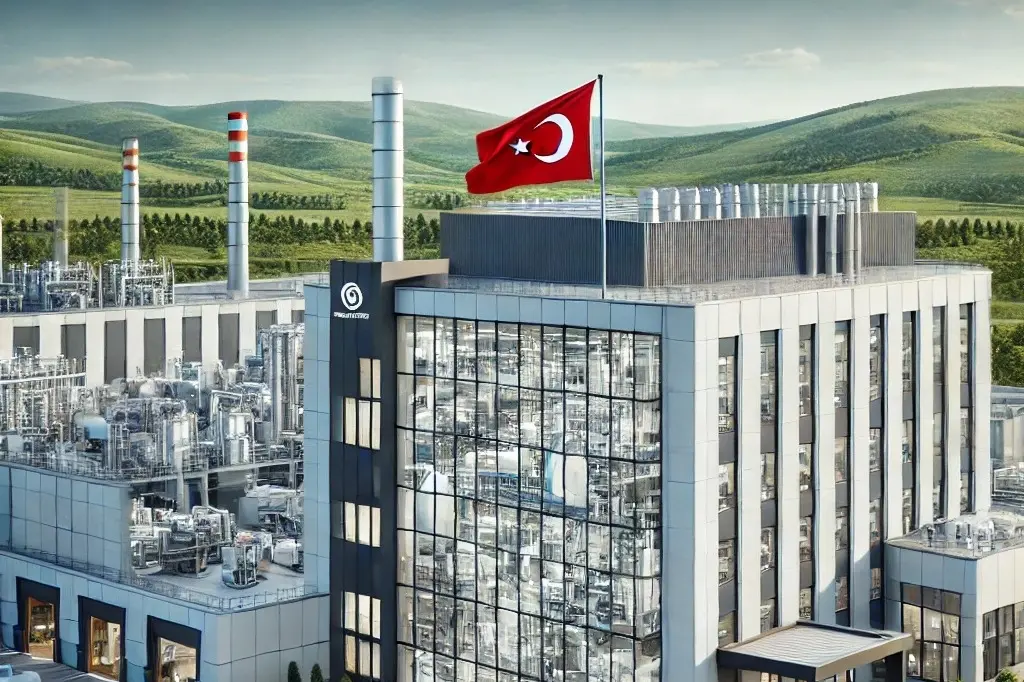

أفضل مصنع البولي ايثيلين

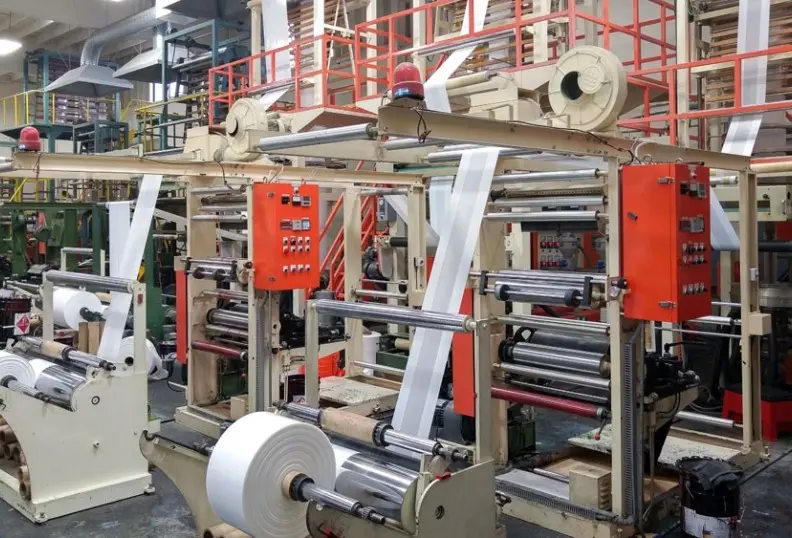

يُعد المتحد لصناعة أكياس المحلات أفضل مصنع أكياس محلات تجارية بالجملة لمختلف المحلات التجارية وبأجود الخامات المتاحة في السوق. نعتمد على تقنيات حديثة في التصنيع وتصميم الأكياس بما يضمن لك أعلى المبيعات والأرباح مع التعزيز من الهوية التجارية.ونعتز بتصدير منتجاتنا إلى مختلف الدول العربية والأجنبية وبأسعار معقولة جدًا. مع مهندسين ومصممين أكفاء يساهمون في حصولك على تصاميم وشكل ومتانة الأكياس التي تحتاجها بالضبط.

نشرع في صناعة أكياس البلاستيك من الصفر إلى التصميم النهائي ولدينا مجموعة واسعة من الأحجام والأشكال، سواء كنت تبحث عن أكياس للتسوق، أو للتخزين، أو للشحن، فإننا نوفر لكم الحل الأمثل.

يمكنك الاتصال بنا للاستفسار عن السعر وطلب كافة أنواع أكياس البلاستيك. ويسعدني الإجابة على أي أسئلة أخرى حول شراء منتجاتنا من البلاستيك.

تركيا: 00905347852222

الامارات: 00971503887373

ختامًا، استخدامات البولي ايثيلين في مجال صناعة الأكياس كثيرة ومتعددة فمختلف الأكياس المستخدمة في عصرنا الحالي مصنوعة من البولي ايثيلين موفرة لسهولة استخدام وجودة عالية للغاية بما يضمن لك التعزيز من تجربة الشراء وتحقيق أعلى رضا ممكن.

الأسئلة الشائعة

ما هي أكياس بولي ايثيلين؟

هي أكياس مصنوعة من بوليمر يتألف من سلاسل طويلة من مونومر الإثيلين من الممكن أن تكون أكياس متعددة الاستخدامات في مجال التغليف والمحلات التجارية مثل المولات والصيدليات وغيرها.

أسعار أكياس بولي ايثيلين؟

تختلف أسعار أكياس البولي إيثلين على حسب المواد الخام المستخدمة والحجم والمقاس.